What is Blister Packaging?

Blister packaging seals a product between a cardboard backing and a clear plastic shell. It’s typically used on smaller commercial and retail goods. Blister packs feature a plastic cavity section where the product fits. A card made of paperboard or foil is then heat sealed to the paper or plastic cavity to secure the product in place.

The Front Side: 3 Types of Blisters

- PET- Blister-Polyethylene Terephthalate made from clear, recyclable plastic

- PVC-Polyvinyl Chloride most used because of cost-effectiveness

Plastic blisters are made of a roll of plastic that is heated and shaped into a cavity or pocket that is either conformed to the product shape or created as a round, square or rectangle cavity called the “blister.” The blister cavity holds the product in place and allows customers to see the product inside the package.

- Paper Blisters are the newest blisters to market

Paper blisters offer the ability to print nice graphics and pictures both inside and outside of the paperboard blister. Paper blisters are made of paperboard instead of plastic, which provides a more sustainable option with recyclable content throughout the entire package.

Paper blister styles include:

- A preformed shell-like paperboard. This is similar to plastic, but typically in round, square or rectangular format (not typically used for other shapes).

- Cardboard type in a cut and fold-style blister for a round/square/rectangle shaped item. This paper option requires some special tooling and equipment, but is typically a little less expensive than the formed paper blister.

The Back Side: What is a Blister Card?

A blister card is a paperboard or corrugated card or backing that can be printed on both front and back with or without color and has a special coating on the card to adhere to a blister on the front, back or even between two cards.

Blister cards offer countless options in styles, colors, textures, foils, embossing, etc. With so many types of finishing on cards, the blister card choice depends on what you want to spend to make your presentation. Thickness is also something to consider, based on how you want to show your product and the style of blister packaging you have chosen.

The two most popular types of paperboard are:

- C1S-SBS. Smooth shiny surface on one side and rough matte finish on the back side.

- C2S-SBS Smooth shiny surface on one side and shiny finish on the back side.

What Types of Blister Packaging Are Right For Your Project?

Face-Seal Blister (Most Common & Most Economical)

A face-seal blister covers just the product. It then is heat sealed to the paperboard or corrugated backing. This form of blister is one of the most economical ways of packaging a product, and it provides both visibility and protection to the product. One downside of a face-seal blister is that the product card can be damaged easier because the card only has plastic where the product is, leaving the cards vulnerable to bending.

Full-Face Blister

A full-face blister covers the entire front of the card and has the formed cavity made into the blister, it is then heat sealed to protect both the card and the product. This style of blister protects cards from bending and adds strength to the packaging. One downside of a full-face blister is that it requires more plastic, which increases cost, and reduces sustainability.

Full-Card Blister or Slide Pack

This style of blister is very similar to a full-face blister, but the plastic wraps around the card, and no heat seal is used. For this style of blister, you simply slide the card into blister and then typically staple the card to the blister. This is an expensive way to package due to the roll-over feature of the blister, which does not feature an automation option and thus is very labor-intensive.

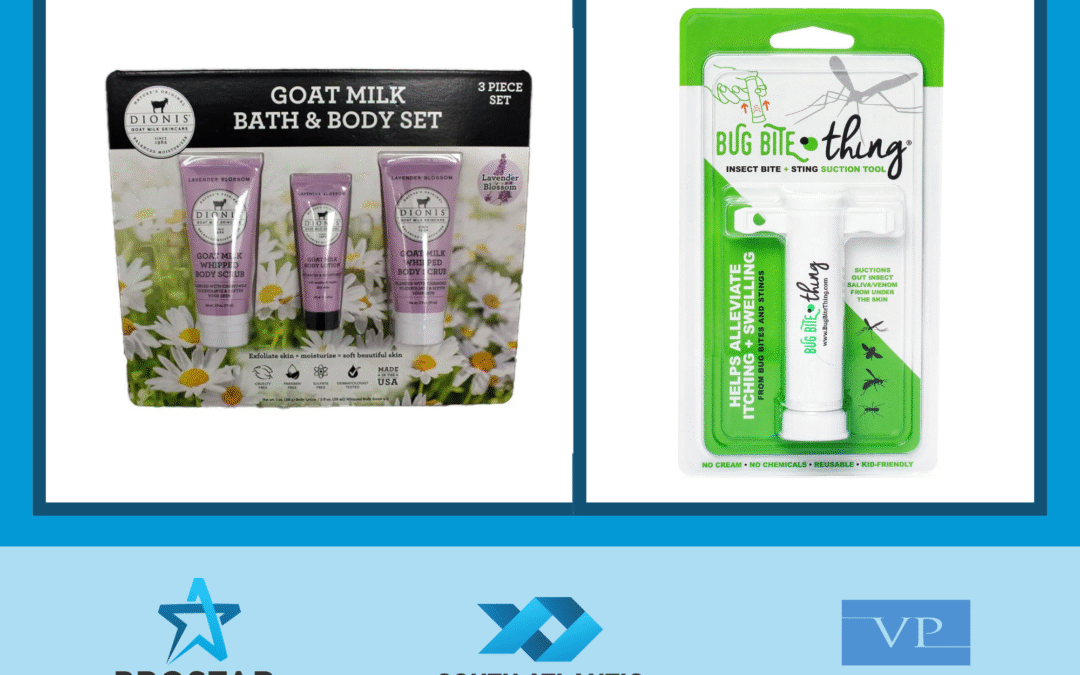

Trapped Blister or Club Store Packaging

This is a process where the front or back card is cut out to the shape of the product, the product is added to the blister and then trapped or sandwiched between two cards and sealed closed. Both paper blisters and plastic blisters can be used in this process. This process strengthens the package and enhances the tamper resistance. It also provides an enhanced appearance since it exposes less plastic and provides more opportunity for printed cards and graphics. One downside is the package size typically is a little larger than that of a face-seal blister, and so is a little more expensive

Paper Blister Packaging

Paper blister packaging is evolving as a new packaging process where paper is used instead of plastic to attach the product to the card. This process is very similar to the heat-seal process for plastic. Paper blister packaging can be done in many of the styles above: Face-Seal, Full-Face Blister and Trapped. The two main reasons to choose paperboard blisters are sustainability and the graphics and illustration options they present to show the product. One downside: tooling and automation can be limited.

Clamshell Packaging

In clamshell packaging two pieces of plastic are hinged together and then RF Sealed, stapled or snap buttoned for the closure. Typically, this style is used for heavy items or high-security type items. Clamshell generally is a slower production process, using more plastic and more paperboard, so it is a lower sustainability and higher cost option.

Form-fill and Seal-Blister Packaging

Form-fill and seal-blister packaging is a process in which the blister is made in line from a roll of plastic, then product is filled into the formed cavity, roll stock paperboard or foil is applied to the back of the blister, and then it is heat sealed and cut to size. This packaging typically is used in pharmaceutical and nutraceutical products. It is a very costly process for the first-time setup cost. Typically, small to medium-size type products are seen in this style of packaging. While this style does not allow much “billboard” space for advertising product messaging, it is a great choice for sealing for freshness and longevity of products with foil backing to plastic style package.